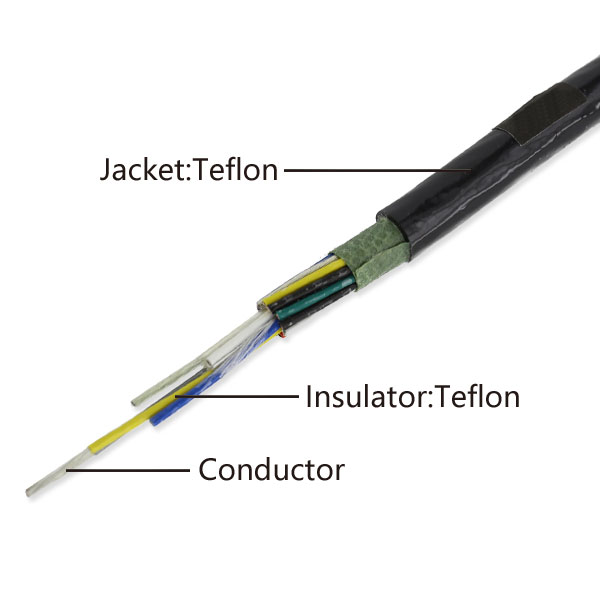

High temperature teflon cable KFF

Applications:

This product is suitable for AC rated voltage 450/750V electrical instru mentation and automatic control system cable transmission line, with oil, water, abrasion, acid and a varity of corrosive gas, anti-aging, non-combustion and excellent performance for metallurgy, electric power, petrochemical and other industries.

Technical Data:

- AC rated voltage: U0/U 450/750KV

- Maximum operating temperature: poly FEP(F46) insulation does not exceed 200'C

- Minimum ambient temperature: PVC sheath:Fixed laying -40'C, non-fixed laying -15'C; Fluorine plastic sheath: Fixed laying -60'C, non-fixed laying -20'C

- Laying of cable installation temperature should not be less than 0'C

- Cable bending radius: Cablebengding radius:non-armored cable a minimum of 6 times the cable diameter;Fluoride plastic insulated and sheathed cable with a minimum of 8 times the cable diameter

Fluorine plastic high temperature CONTROL cables

| Basic Model and name | |

|---|---|

| Type | Product Name |

| SKFF | Fluorine 46 (FEP) insulated and sheathed control cable |

| KFFP | Fluorine 46 (FEP) insulated and sheathed copper braided shield control cable |

| KFFRP | Fluorine 46 (FEP) insulated and sheathed copper braided shield flexible control cable |

| KFFP1 | Fluorine 46 (FEP) insulated and tinned copper braid sheath control cable |

| KFFRP2 | Fluorine 46 (FEP) insulated and sheathed copper shield around the control cable package |

| KFV | Fluorine 46 (FEP) insulated PVC sheathed control cable |

| KFVR | Fluorine 46 (FEP) insulated PVC sheathed control cable |

| KFVRP | Fluorine 46 (FEP) insulated copper wire braided shield PVC sheathed control cable |

| KFGR(YGC-KF46R) | Fluorine 46 (FEP) silicone rubber insulated control cable sheath |

| KFGPR(YGC-KF46RP) | Fluorine 46 (FEP) silicone rubber insulated wire braided shield sheath control cable |

| Conductor | Insulation | Jacket | Electrical Properties |

|||

|---|---|---|---|---|---|---|

| Sectional Area mm² |

Conductor Construction NO.XΦmm |

Insulation Thickness mm |

Outer Diameter mm |

Jacket Thickness mm |

Average Diameter mm |

Max.Conductor Resistance DC 20'C Ω/km |

| 2x0.35 | 19/0.16 | 0.25 | 1.3 | 0.25 | 3.1 | 49.5 |

| 3x0.35 | 19/0.16 | 0.25 | 1.3 | 0.25 | 3.2 | 49.5 |

| 4x0.35 | 19/0.16 | 0.25 | 1.3 | 0.25 | 3.65 | 49.5 |

| 5x0.35 | 19/0.16 | 0.25 | 1.3 | 0.3 | 4.1 | 49.5 |

| 6x0.35 | 19/0.16 | 0.25 | 1.3 | 0.3 | 4.5 | 49.5 |

| 7x0.35 | 19/0.16 | 0.25 | 1.3 | 0.3 | 4.5 | 49.5 |

| 2x0.5 | 19/0.18 | 0.25 | 1.4 | 0.25 | 3.3 | 36 |

| 3x0.5 | 19/0.18 | 0.25 | 1.4 | 0.25 | 3.4 | 36 |

| 4x0.5 | 19/0.18 | 0.25 | 1.4 | 0.3 | 4 | 36 |

| 5x0.5 | 19/0.18 | 0.25 | 1.4 | 0.3 | 4.4 | 36 |

| 6x0.5 | 19/0.18 | 0.25 | 1.4 | 0.3 | 4.8 | 36 |

| 7x0.5 | 19/0.18 | 0.25 | 1.4 | 0.3 | 4.8 | 36 |

| 2x0.75 | 19/0.23 | 0.25 | 1.7 | 0.3 | 4 | 22.7 |

| 3x0.75 | 19/0.23 | 0.25 | 1.7 | 0.3 | 4 | 22.7 |

| 4x0.75 | 19/0.23 | 0.25 | 1.7 | 0.3 | 4.7 | 22.7 |

| 5x0.75 | 19/0.23 | 0.25 | 1.7 | 0.35 | 5.3 | 22.7 |

| 6x0.75 | 19/0.23 | 0.25 | 1.7 | 0.35 | 5.8 | 22.7 |

| 7x0.75 | 19/0.23 | 0.25 | 1.7 | 0.35 | 5.8 | 22.7 |

| 2x1 | 19/0.26 | 0.25 | 1.8 | 0.3 | 4.2 | 19 |

| 3x1 | 19/0.26 | 0.25 | 1.8 | 0.35 | 4.3 | 19 |

| 4x1 | 19/0.26 | 0.25 | 1.8 | 0.35 | 5.1 | 19 |

| 5x1 | 19/0.26 | 0.25 | 1.8 | 0.35 | 5.6 | 19 |

| 6x1 | 19/0.26 | 0.25 | 1.8 | 0.4 | 6.2 | 19 |

| 7x1 | 19/0.26 | 0.25 | 1.8 | 0.4 | 6.2 | 19 |

| Code names and meanings | ||

|---|---|---|

| Name | Code | Meaning of codes |

| series of codes | K | Control cable |

| Insulation materials | F | Poly FEP(F46)maximum operating temperature of 200'C |

| Soluble Teflon (PFA)maximum operating temperature of 260'C | ||

| Sheath material | F | Poly FEP(F46)maximum operating temperature of 200'C |

| Soluble Teflon (PFA)maximum operating temperature of 260'C | ||

| V | Polyvinyl chloride (PVC) | |

| G | Silicone rubber | |

| Flame retardant properties | ZR(V) | Flame retardant PVC(Three kinds of 70'C、90'C、105'C) |

| The main technical indicators | ||

| Finished cable conductor DC resistance (in accordance with the provisions of GB3956) | ||

| 20'Cwhen the insulation resistance of not less than 500MΩ/KM | ||

| Finished cable communication 50HZ3.0KV/5min withstand voltage test without breakdown | ||

+86-21-63522508

+86-21-63522508 +86-21-60835900

+86-21-60835900